Abstract

Margarine macmacaanku waa inuu ahaadaa caag oo joogto ah.Qulqulka farsamada soo saarida margarine macmacaanka ah waxa si fudud u habayn kara tuubo-chiller.Inta lagu jiro habka qoto-dheer ee saliidda, qaboojintu waxay saameyn weyn ku leedahay crystallization ee margarine macmacaanka ah.Margarin kala duwan waxay u baahan tahay nidaam kala duwan iyo xaalad heerkulka.

Margarine macmacaanku waa inuu ahaadaa caag oo joogto ah.Qulqulka farsamada soo saarida margarine macmacaanka ah waxa si fudud u habayn kara tuubo-chiller.Inta lagu jiro habka qoto-dheer ee saliidda, qaboojintu waxay saameyn weyn ku leedahay crystallization ee margarine macmacaanka ah.Margarin kala duwan waxay u baahan tahay nidaam kala duwan iyo xaalad heerkulka.

Erayada muhiimka ah: margarine macmacaanka;durbaanka qaboojinta;qaboojiyaha tuubada, kulaylka dusha sare ee la xoqay, wax soo saarka margarine.

Soo bandhigida farsamada ee qaboojiyaha tuubada

Inkasta oo badeecada margarine-ka jilicsan ay ku jirtay wax soo saarka sanado badan, dadku waxay isku dayayeen inay ogaadaan habka ugu wanaagsan ee xaaladaha habka, badiyaa ku saabsan crystallization ee caanaha alaabta kala duwan ee hoos yimaada xaaladaha kala duwan ee habka.Kahor intaan la abuurin qalabka wax lagu beddelo kulaylka, ama mashiinka deminta tuubada, dhammaan badeecooyinka margarine waxaa la soo saaray iyadoo la isticmaalayo durbaanka deminta iyo mashiinnada cajiinka.Sababtoo ah mishiinka farsamaynta tuubada ayaa leh faa'iidooyin badan marka la barbar dhigo mishiinnada kale ee wax lagu sameeyo, sidaas darteed hadda soo saarayaasha margarine waxay isticmaalayaan wax soo saarkooda margarine macmacaan ah, warqadan mashiinka farsamaynta tuubada deminta si ay u soo saaraan habka margarine macmacaanka ah si ay u sameeyaan waxoogaa hordhac ah.

Astaamaha ugu muhiimsan ee margarine jajaban waa caagnimada iyo xasilloonida.Marka margarine la duubo oo la soo rogo si isdaba joog ah, lakabyadu waa inay ahaadaan kuwo aan jabin oo cajiinka ah, sidaas darteed caaggu waa muhiim;Xasiloonida sidoo kale waa muhiim.Haddii margarinku aanu ku filnayn inuu noqdo mid jilicsan ama saliid ah, oo la nuugo cajiinka, lakabka saliidda ee u dhexeeya lakabyada cajiinka ayaa si weyn loo dhimi doonaa.

Qaab dhismeedka mashiinka dab-deminta durbaanka rotary waa mid fudud, kaliya waxay u baahan tahay in la hagaajiyo dhowr cabbir wax soo saarka ayaa soo saari kara alaabada margarine ee qallafsan.Margarine-ka keega ah ee jilicsan ee uu soo saaro mishiinka durbaanka ayaa leh caag wanaagsan, ma fududa in la geliyo saliidda, aad ayuuna u deggan yahay heerkul ballaaran.Mashiinka deminta tuubada marka loo eego mishiinka durbaanka wax qabadkiisa waxa uu sameeyay horumar weyn, kaas oo inta badan ka muuqda:

(1) In alaabada farsamaynta tuubooyinka la xidhay, xidhidhiyaha wanaagsan, xaaladaha nadaafadda ayaa sidoo kale wanaajin doona wax badan;

(2) Xaqiijinta hawlgalka cadaadiska sare, kaas oo si gaar ah muhiim ugu ah soo saarista margarine qallafsan;

(3) Dabacsanaan wanaagsan, waxay si dabacsan u beddeli kartaa xawaaraha, cadaadiska, xoogga qaboojinta iyo xaaladaha kale ee habaynta.

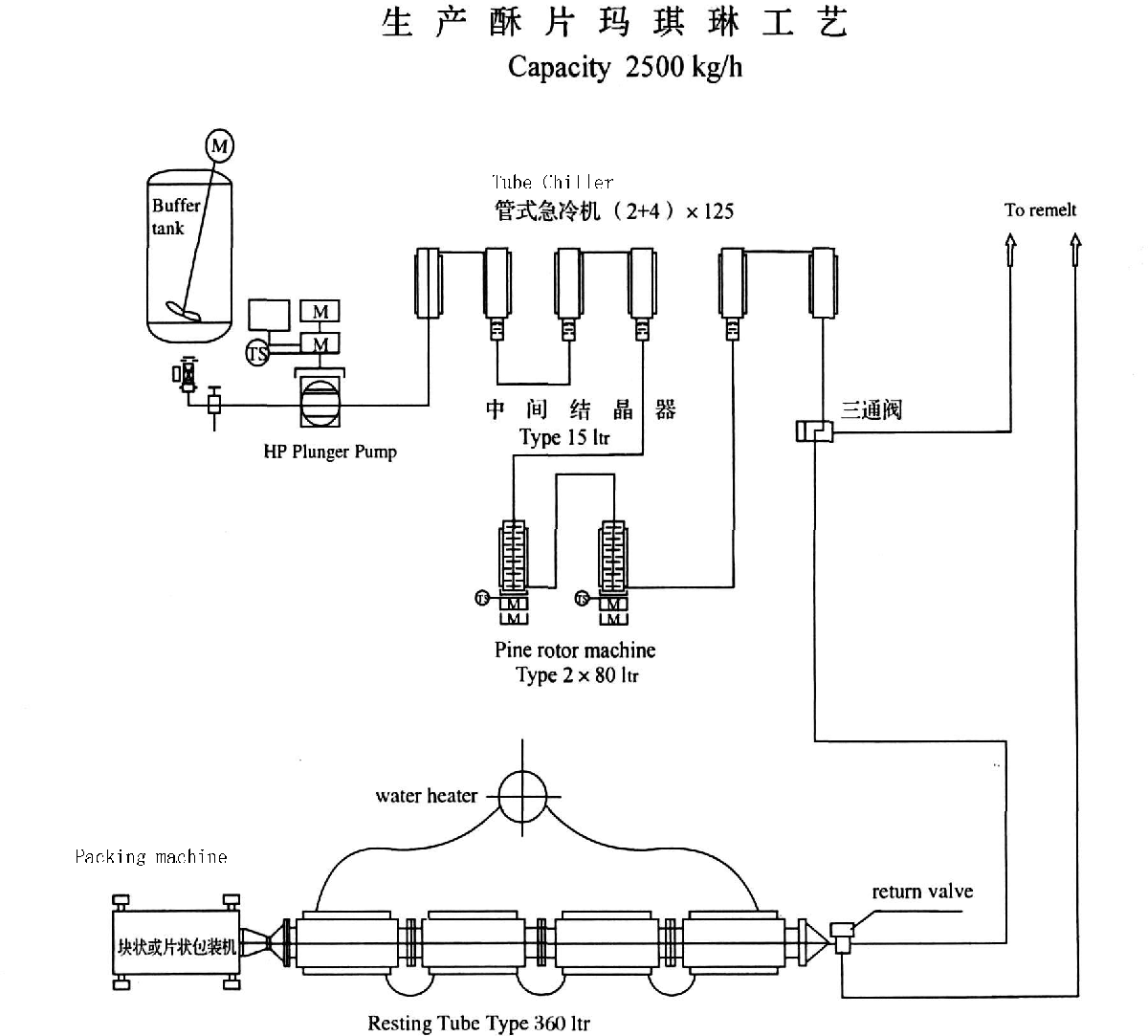

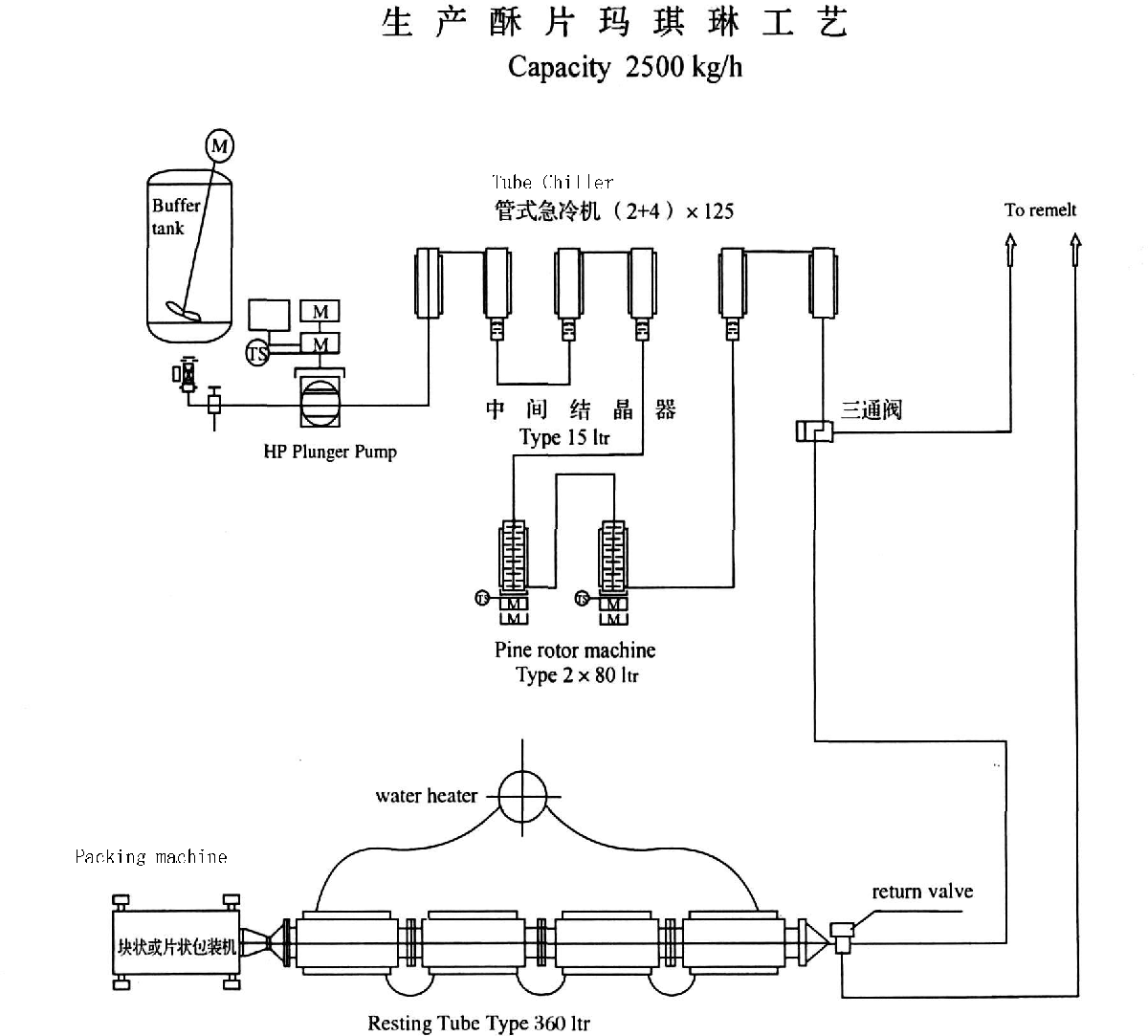

Habka wakiilka ee soo saarida margarine macmacaan jilicsan oo loo isticmaalo mashiinka deminta tuubada waa sida soo socota:

Bamka tuubada cadaadiska sare ※ tuubada cadaadiska sare xoqan weelka kulaylka dusha sare (Unit A) ※ Qalabka crystallizer dhexdhexaad ah ※ Mashiinka rotor-ka ee geedka kicinta (Cutubka B) ※ Tuubbada nasashada ee awoodda weyn

Shaqada crystallizer-ka dhexdhexaadka ah waxay u dhigantaa tan cajiinka.Waxay ku taalaa tuubada demi ee mishiinka farsamaynta oo loo kaxeeyo si ay u wareegto usheeda dhexe ee mishiinka farsamaynta.

Way ku habboon tahay in la hagaajiyo socodka socodka alaabta si loo soo saaro margarine macmacaan jilicsan oo leh mashiinka deminta tuubada.Ujeedada habraaca habraaca waxa lagu gaadhi karaa iyada oo la beddelo habka isku xidhka tuubada isku xidha ee u dhaxaysa kooxda tuubooyinka demi (cutubka A) iyo unugga cajiin (cutubka B), kaas oo fudud in la shaqeeyo.Tusaale ahaan, unugga cajiinka (cutubka B) waxa lagu dhejin karaa badhtamaha tuubada demi ee unugga, iyadoo la raacayo qulqulka A 1 ※A 2 ※B1 ※B2 ※A 3※A 4, ama loo beddelo qulqulka ee A 1※A 2※A 3※A 4※B1※B2.Adigoo si fudud u beddelaya habka hab-socodka waxay hagaajin kartaa tayada alaabta.Habka kor ku xusan, habka loo dhigo cutubka B ee bartamaha tuubada quench ee cutubka A ayaa si gaar ah ugu habboon samaynta saliidda khudradda ee ku salaysan saliidda timirta, taas oo marar badan lagu caddeeyey waxqabadka wax soo saarka.Iyo marka alaabta ugu muhiimsan ee alaabtu ay tahay lo'da, natiijooyin wanaagsan ayaa lagu heli karaa iyada oo la dhejiyo cutubka B ka dib cutubka A.

Awoodda cajiinka waxaa lagu go'aamiyaa samaynta badeecada, tusaale ahaan, awoodda wax lagu cajiin karo waa in loo isticmaalo samaynta saliidda oo leh crystallization tartiib tartiib ah.In habka wax soo saarka tuubada qaboojinta degdeg ah, saamaynta cajiintu waa awoodda kooxda dhexe iyo awoodda crystallizer iyo karbaash unugga cajiin (B) wadarta awoodda cutubka, sidaas darteed marka isbedel in formula alaabta, baahida loo qabo. si loo hagaajiyo awoodda habka cajiinka, iyada oo loo marayo kororka awoodda halbeegga B ama hoos u dhaca, kordhinta ama hoos u dhigi karta awoodda caaryada dhexe, Waxaa xitaa la samayn karaa iyada oo lagu daro oo laga jarayo isla waqti isku mid ah, aad u jilicsan.

Awoodda cajiinka waxaa lagu go'aamiyaa samaynta badeecada, tusaale ahaan, awoodda wax lagu cajiin karo waa in loo isticmaalo samaynta saliidda oo leh crystallization tartiib tartiib ah.In habka wax soo saarka tuubada qaboojinta degdeg ah, saamaynta cajiintu waa awoodda kooxda dhexe iyo awoodda crystallizer iyo karbaash unugga cajiin (B) wadarta awoodda cutubka, sidaas darteed marka isbedel in formula alaabta, baahida loo qabo. si loo hagaajiyo awoodda habka cajiinka, iyada oo loo marayo kororka awoodda halbeegga B ama hoos u dhaca, kordhinta ama hoos u dhigi karta awoodda caaryada dhexe, Waxaa xitaa la samayn karaa iyada oo lagu daro oo laga jarayo isla waqti isku mid ah, aad u jilicsan.

Waqtiga boostada: Dec-30-2021